Water-fuel emulsion

New technology for water-fuel emulsion production for power stations, industrial boilers and ship power installations (ship engines).

- The usage of water-fuel emulsions has a number of advantages: fast and practically total combustion of emulsion, low temperature of preliminary heating of emulsion, decreasing of output of poly-aromatics cancer components (more than 10 times), carbon monoxides (about 40%) and nitrogen oxides (10 – 15%) to the ambience.

- The usage of water-fuel emulsions on power stations allows substantially save fuel-oil with minimum reconstruction. The payback period of reconstruction is a few months.

- The ratio of water to fuel can vary up to 50%. Maximum economy and environment efficiency can be achieved on about 10 – 30% of the ratio.

- Successful usage of water-fuel emulsion totally depends on the quality of it preparation that are homogeneity and fine-dispersed structure.

- We developed the modern technology of water-fuel emulsion production which is based on effects of hydrodynamics cavitation and production of time sustainable and homogeneous fine-dispersed emulsions. The developed installation can produce up to 30 ton per hour of water-fuel emulsion.

|

|

|

|

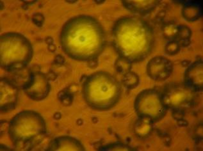

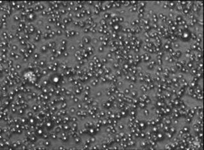

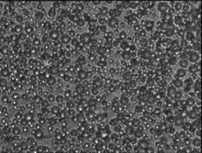

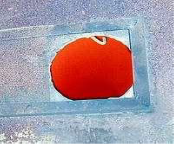

Photos of water-fuel emulsion with different concentration of water – upper left has 17%, upper right has 25%, bottom left has 40% and bottom right is scale on 10 micron.

Combustion of standard fuel-oil and water-fuel emulsion